What is a conductive slip ring? How is it classified?

Publish Time:2023-03-27 Author:jiaxi Views:1788

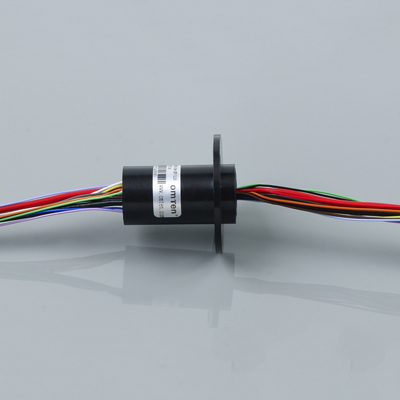

Conductive slip ring, also known as collector ring, slip ring, collector ring, sink ring, rotary joint, rotary electrical interface, coil, commutator, adapter, is a precision power transmission device that realizes data, signal and power transmission of two opposing rotating structures. It belongs to the category of electrical contact sliding connection applications and is well suited for applications in unrestricted continuous rotation.

The electrically conductive slip ring can be divided into cylindrical and disc type according to its structure. The ring path of cylindrical slip ring is arranged along the axis of the cylinder, and the ring path of disc type slip ring is concentric. Cylindrical slip rings are mainly used in China at present, and disc slip rings are used when restricted by height conditions.

Transmitting signals from stationary equipment to shaped rotating equipment is the main role of the conductive slip ring. It can be seen on equipment such as photoelectric measurement, astronomical navigation, and photoelectric search. At the same time, the conductive slip ring is also a core component of various precision rotary tables, piping equipment and centrifuges in cutting-edge fields.

The lower the contact resistance of the conductive slip ring, the better. When the contact resistance of the slip ring is high, the temperature at the contact will increase significantly when the current passes through, and in severe cases, it will lead to an increase in contact pressure drop and melt welding of the brush wire and slip ring. These problems can affect the information transmission effect of the conductive slip ring.

In addition, the pressure, material, and form of contact between the slip ring and the brushes can have an effect on the contact resistance.

1) The effect of contact material on resistance. Conductive slip ring mainly includes ring brush and conductive ring two main devices. This requires the conductive ring to have not only very good thermal conductivity, wear resistance, oxidation resistance, corrosion resistance and resistance to fusion welding and other properties, but also a fairly strong hardness and high melting point.

2) Brush wire pressure on the slip ring. Ring brush is an important component of the conductive slip ring, with the number of brushes, fine brushes, tiny spacing and other advantages. Brush wire pressure on the slip ring will directly affect the size of the contact resistance, the greater the pressure, the smaller the contact resistance. But there is a limit to the increase in pressure, once the limit is exceeded the friction torque will increase, so that the contact part of the wear increases. Therefore, it is important to determine the size of the pressure of the brush wire on the slip ring. This pressure should ideally enable the brush wire to be well pressed on the slip ring without affecting the rotation of the slip ring. Experiments have shown that a pressure of 12 to 15 Newtons is optimal.

In the working process of the conductive slip ring, the relevant personnel need to test its form factor, static contact resistance, dynamic contact resistance, insulation resistance, electrical strength and friction torque and other parameters, the performance of these parameters will have a great impact on its working stability, reliability and life. Timely parameter testing of the conductive slip ring to better reflect the performance of the conductive slip ring, but also the first time to find and solve the problem.

简体中文

简体中文 English

English Español

Español Pусский

Pусский