Conductive slip rings are used in which machinery and equipment

Publish Time:2022-12-21 Author:jiaxi Views:725

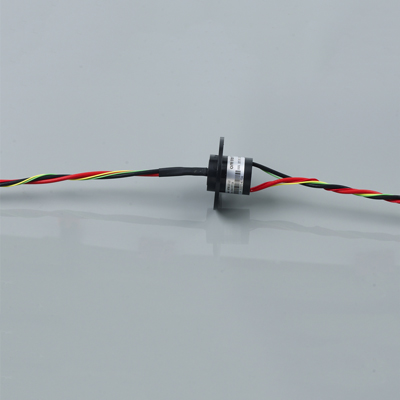

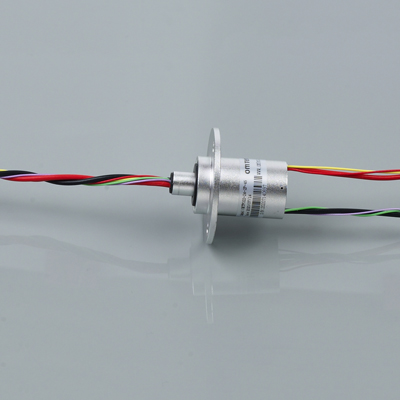

Conductive slip rings are a product of modern industrial development required for a reliable electrical connection between two relatively rotating parts. Conductive slip ring is also called collector ring, or rotary joint, rotary electrical interface, slip ring, collector ring, return ring, adapter. It is composed of elastic material, brush, sliding contact surface material, conductive ring, insulating material, bonding material, combination bracket, precision bearing, dust cover and other conductive slip ring. There are three main structures of conductive slip rings, one is cap conductive slip ring, one is over-hole conductive slip ring, and the other is disk slip ring. So, what is the cap conductive slip ring? As the name implies, because it looks like a hat, so the industry called the cap conductive slip ring, mainly from the appearance of the distinction. There are two main types of conductive slip rings, one is based on the conductive medium, such as electric slip rings, fiber optic slip rings, mercury slip rings, etc. The other is based on the conductive slip ring structure, such as over-hole (also known as hollow shaft slip ring), cap, disk slip ring, etc.

Typical applications of conductive slip rings are more examples: as long as the rotating equipment can use standing conductive slip rings, such as security equipment, resistance cutting machine, rotating work plate signal and current mixing, horizontal copper plating production line, rotating stage, cable coil, circular knitting machine, intelligent dynamic toys, robot precision dynamic detector, intelligent household appliances, single crystal furnace, circular knitting machine, glucose production equipment, beer production equipment, dairy production equipment drilling equipment, helicopters, radar communication equipment, aviation equipment tanks, revolving doors, production lines, in-tube cameras, rotating silver plating production lines, surgical lights, robotic arms, dyeing equipment, LED rotating advertising lights, molding machines, winding machines, wind generators, lifting equipment, road and bridge machinery, shield hooks, full drilling machines, tanks, various armored vehicles, turret rotation systems, radar, etc.

In the electrical design process, when the mechanical parts rotate continuously, the wires need to be connected to the rotating parts, and the electrical engineer will encounter the wire winding problem. At this point, he needs a motorized rotary connector, often called a motorized sliding ring to transmit power and signal to the rotary connection.

It can improve system performance, simplify the system structure and avoid wire kinking when rotating. In short, the conductive sliding ring can improve the system performance by simplifying the operation to improve the system performance. You can refer to the following pictures.

In order to ensure complete contact between the brush and the conductive ring of the conductive slip ring, the conductive ring is designed to be U. In addition, its internal brush assembly is machined and molded using precious metal alloy wire. Brush materials include: beryllium copper, silver-nickel alloy, gold-nickel alloy, silver-graphite, copper-graphite synthetic brushes, brush wire sliding contact with the U ring groove through elastic pressure to transmit signals and currents, therefore, the brush material has very good conductivity, proper elastic pressure to reduce eccentricity and rocking deviation, good wear resistance, low friction torque, and easy maintenance. Shielding, impedance matching, noise voltage, etc. should also be considered.

Application fields: industrial machines: drilling platform, winding machine, end processing machine, hot rolling machine, rotary table: winding machine, filling machine, bottle blowing machine, amusement equipment, cable reel: port machinery, lifting equipment, road and bridge machinery, tower. , test equipment: centrifugal test stand, separator, test instrument machine. , robot: packaging equipment, stacker, process control equipment, press machine, exhibition/display equipment: car booths, revolving doors, product booths, revolving restaurant, medical equipment: shadowless surgical lights, helicopters, radar communication equipment.

简体中文

简体中文 English

English Español

Español Pусский

Pусский