Conductive slip ring operation and maintenance

Publish Time:2023-02-14 Author:mengyuan Views:1870

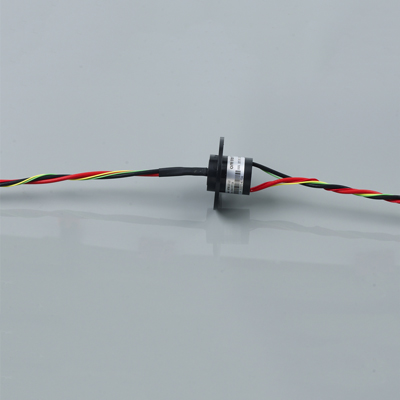

A conductive slip ring is an electromechanical component that can transmit current and data signals from a fixed device to a rotating device, also known as a conductive ring, collector ring, sink ring, brush, rotating electrical joint or electrical rotary head. Slip rings can be used in any electromechanical system that requires unrestricted continuous rotation and have been widely used in amusement, communication, security, electric power, instrumentation, chemical, medical, radar, aviation, military, shipping, transportation, construction, industrial automation and other electromechanical equipment.

Conductive slip ring is the use of conductive ring sliding contact, electrostatic coupling or electromagnetic coupling, in the fixed seat frame rotating parts and rolling or sliding parts between the transmission of electrical signals and electrical energy transfer of precision transmission device. It is widely used in all electromechanical systems that require unrestricted, continuous or intermittent 360 degree rotation to provide multiple channels of rotational power, data and signals. It greatly simplifies the system structure and avoids kinking of wires during rotation. The understanding of the structure of the conductive slip ring is very important, because the product itself in all the flower ring series is very widely used, and more dedicated to some unrestricted continuous rotation process, including the stator and rotor parts, respectively, and the wire will be connected and fixed, according to the overall structure of some differences, can also be divided into different types. The specific effects of the different types of products in the process of use are also completely different. The use of this product can continue to improve the performance of the system, but also to simplify the structure of the system, the main thing is to avoid the wire in the rotation of a certain damage, especially through such a form, can continue to simplify the operation, and to eliminate damage, effectively improving the performance of some systems.

At a basic level, slip rings consist of two main components, the conductive ring and the brushes, either the conductive ring rotates - the brushes are stationary - or the brushes rotate - the conductive ring is stationary, there is no essential difference between these two operating states. To protect them from dust, moisture and other factors that may cause their failure, if the use environment is better, usually also made into engineering plastic housing, the cost is lower, and conductive slip ring is not easily damaged. Copper ring rotation, brush wire fixed, the number of wires at both ends of the device is certainly one to one, the route in, the route out, the stator brush wire contact with the copper ring when the wire is divided into 2 ways each, mainly to prevent a route damage, the other can still work normally. The brush contacts are always in pairs, one in two to prevent damage to one way and the other to work, made of metallic copper graphite or silver graphite (now basically ternary alloy wire, more robust and wear-resistant) and rubbing against the outside of the rotating metal ring, which maintains a continuous electrical connection as part of the assembly rotates, although there is usually only one brush pair per ring. But varying current strengths may require the use of four or even more pairs per circuit. The diameter of the ternary alloy wire is generally fixed, and when encountering high-current devices, dozens of brushes may be used in combination each way to ensure that they do not burn out at high currents.

简体中文

简体中文 English

English Español

Español Pусский

Pусский